Blue Tree Systems

Blue Tree Systems

Blue Tree Systems

Blue Tree Systems

Blue Tree Systems designed and manufactured Fleet Management systems for the commercial vehicle industry.

(Blue Tree was acquired by Orbcomm in 2017)

I managed the hardware team, comprising 5 engineers.

Blue Tree's hardware products were designed around embedded microcontroller platforms, with a variety of peripherals supported.

These included wireline interfaces such as RS-232, CAN, J1708, and K-line;

and wireless interfaces such as ISM-band 2.4GHz, GSM, and GPS.

I was responsible for all hardware products, from initial design concept, through prototyping, test, and

approvals, to manufacture.

I personally completed all hardware design tasks: specification and selection of components, circuit design,

simulation, schematic capture, and PCB layout.

I would also liase with contract manufacturers, design wiring harnesses, and document installation procedures

for all vehicle types.

For firmware development, I managed the team: selected tool-chains, drove continuous improvement in coding and

testing processes, and monitored verification and validation results.

In a small company, my greatest challenge was in maintaining product quality and design integrity in a

high-pressure environment with limited resources and constantly changing requirements.

Key customers were often directly involved in product definition or customisation. Roles and

responsibilities were fluid, so I was also involved in software engineering, sales and marketing,

operations, and production.

Blue Tree Systems was traditionally focussed on software development for Thermo King Corporation.

I was taken on to lead and develop the hardware function as the company expanded into other markets.

The “R:COM” Fleet Management product-line is now a recognised world leader in the area of vehicle telematics and logistics.

The company’s development methodology could best be described as "agile"!

Requirements were poorly defined, so hardware flexibility was critical in order to react to late-changing specifications.

In chronological order, I developed the following products:

| RTL | The “R:COM Temperature Logger” provides 4 temperature sensors and 2 door switch inputs for temperature monitoring applications. Housed in an IP67 enclosure, it communicates with an R:COM module via RS-232. Based on a TI MSP430 microcontroller and NTC thermistor sensors, it achieves an accuracy of ±0.5°C from -35 to +60°C. |

| R:COM 2400 | This device represented the third generation of the original R:COM transceiver. With a frequency-hopping 2.4GHz radio, it provides approximately 1km of range. On-board features include RS-232, CAN (ISO 11898) and SAE J1708 interfaces, digital I/O, 1MB of data flash, and an RTC. Together with the RTL, this product was designed to meet the requirements of the ATP agreement on the transport of foodstuffs in the European Union. It was independently certified by TÜV Süddeutschland to EN 12830 and the German TLMV directive. Based on a Dallas/Maxim 8051 microcontroller. |

| R:COM Tracker | This was an evolution of the R:COM 2400 module, but with a GSM modem instead of the ISM-band radio. The design went through several iterations during its lifetime, due to component obsolescence, enclosure changes, and new features. The most recent implementation includes a quad-band GPRS/EDGE modem, a GPS receiver, a fuel-gauge interface and an accelerometer. |

| REM |

The “R:COM Expansion Module” adds extra I/O to the R:COM module (2400 or Tracker), with which it

communicates via CAN. Interfaces include CAN for engine connectivity, 1-Wire for driver ID, RS232

for digital tachograph downloading, K-line for live tachograph data, and general-purpose analogue

and digital I/O. An optional 12V, 1W power supply can be included for powering a third-party device

such as sat-nav. The CAN interface is available in two stuffing options: listen-only ISO 11898 for SAE J1939, and bi-directional ISO 15765-4 for OBD. Based on a Freescale S12 micro. |

| R:COM Dot | This module was designed to be a subset of the R:COM Tracker, but with a backup battery allowing it to be used for tracking un-powered assets such as dry trailers. The solution I designed allows use of either a primary Lithium battery for maximum lifetime, or a re-chargeable Lithium-Ion battery for extra flexibility. Based on a Wavecom “Wireless CPU”, a typical configuration of 1 location update per day gives a battery life of over 1 year. A CDMA variant is available in areas where GPRS coverage is poor. |

| R:COM 4 |

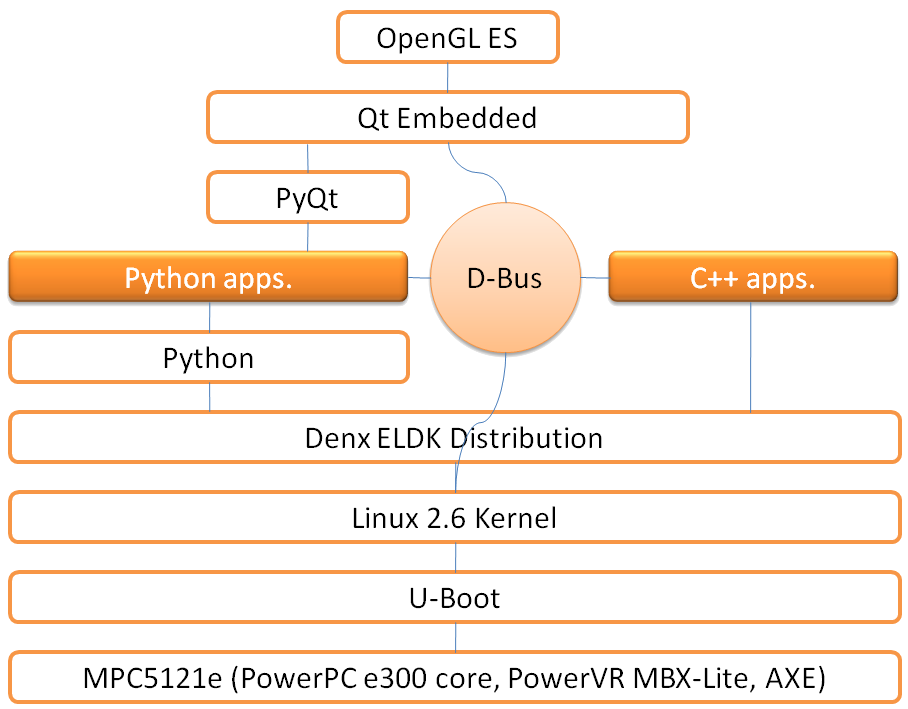

This fourth generation platform was to be a high-end solution for an in-cab PC. It effectively combines

the functionality of the existing R:COM Tracker and REM with a touch-screen display and driver-centric USB.

All layers of the hardware/software stack were carefully chosen for a combination of high

performance, low cost, and maximum flexibility for development. Key suppliers were chosen for long-term

availability and strategic relationships.

|